Quality Assurance

As each project is different, we follow a rigorous quality path to capture all of the requirements at the outset of each new build.

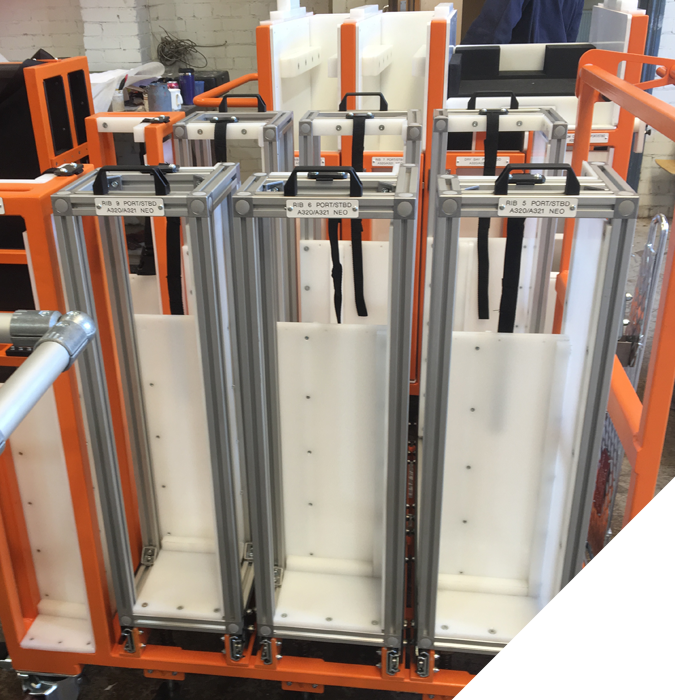

We offer a full testing process for all of our fabrications such as the Aircraft Engine Ground Support Frames we produce.

With an accreditation to ISO9001:2015, EN 1090 and Rolls Royce Nuclear we are a capable team of engineers who are ready to support any new project.

Traceability

Full traceability of all materials together with all internal testing of welding can be provided as required.

We are able to carry out load testing to stringent aerospace standard and we are familiar with working up to 40 Tonne point loading on structural frames.

The Certification pack that we can provide might include Material Certificates for traceability, Welding Certificates, Welding Maps and Procedures, Furnace Charts, NDT reports, Visual Inspection Reports, Shot Blast and Painting Reports and our Certificate of Conformity.